Barmag filter: High efficiency bar-type magnetic separators

Firma Stevens - Hydrobelt BARMAG units use powerful permanent magnets encased in stainless steel tubes which are very effective for separation of magnetic fines from liquids in the high and low micron size range. Due to the low velocity of the liquid flowing through a densely concentrated magnetic field, very fine magnetic particulates can be removed.

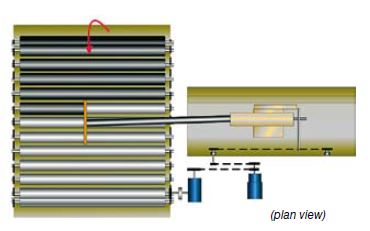

Dirty liquid enters the tank at the bottom and flows evenly between the magnetic bars which are spaced very closely together. Distribution panels located behind the magnetic bars insure that the liquid flows at a uniform velocity through the entire magnetic field. Velocity is held below 2 in/sec (50 mm/sec). Magnetic particles are attracted to the magnetic bars. The bars are attached to stainless steel drive chains that slowly and continuously index the bars through the separation tank. At the top of the chain loop is a bar wiper cleaning station. The sludge drops into an auger trough where it is removed and discharged into a sludge holding tank.

Applications

These units are used extensively in the steel industries (cold rolling emulsions, strip cleaning solutions) and in the metal working market (fine grinding, honing, and polishing of steel, cast iron and powder metal materials).

Animation

For removal of fine magnetic suspended solids

Operating

The bar-wiping mechanism operates as follows. On the forward stroke the wipers are closed and remove the sludge from the bars. On the return stroke the wipers are open. Three bars are wiped simultaneously, so each bar is wiped three times. One complete cycle of the wiping mechanism coincides with the bars advancing one position along the chain loop.

The bar-chain and wiping mechanism are synchronized and driven by a variable speed drive. Wiper speed is adjustable and ranges from zero to five bar strokes per minute. Controls allow for intermittent operation.

Bar cleaning device during the cleaning stroke

Bar cleaning device during the idle stroke

Drive of the bar cleaning device and of the bar chain are synchronized

Bar-type magnetic separator

There are several types of magnetic separators. Vertical units are the most common ones and can be built ranging from the smallest unit, model M45B, up to M222B (45 to 222 magnetic bars).

Hi-flow bar-type magnetic separator

Larger units are built in the “L”-shape configuration. These units will go up to M300BL sizes.

Bar-type magnetic separator/drag conveyor

For applications with heavy dirt loads the possibility exists that settling can take place in the magnetic separator tank. For these applications we recommend a drag conveyor in the bottom of the tank. Magnetic

separators can also be suspended in existing tanks rather than built in their own tank.

Examples